Milk Processing Equipments

We are Manufacturer, Supplier, Exporter of Milk Processing Equipments ,Milk Chillers, Milk Pasteurisers, Milk Inline Strainers, Milk Silos, Milk Weigh Bowls, Dump Tanks & Float Balance Tanks, SS Milk Pumps - Process / Evaporator Types, Horizontal Insulated Milk Storage Tanks, Vertical Insulated Milk Storage Tanks, Cream Ripening Tanks, Cream Separators - Inline Types & Cream Pasteuriser from Pune, Maharashtra, India.

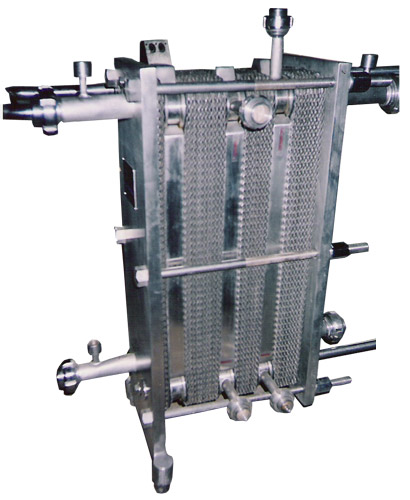

Milk Chillers

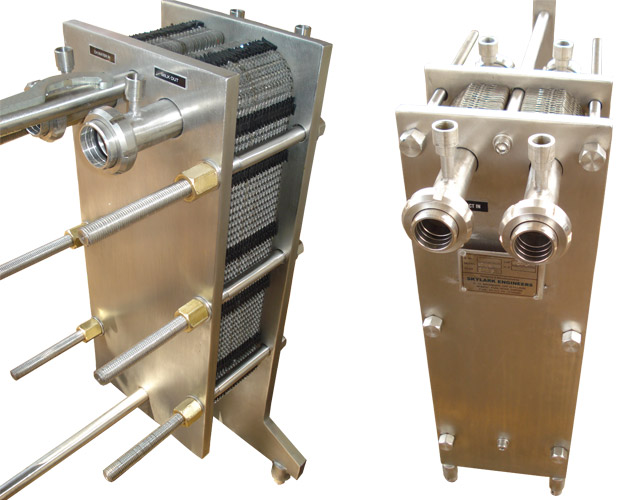

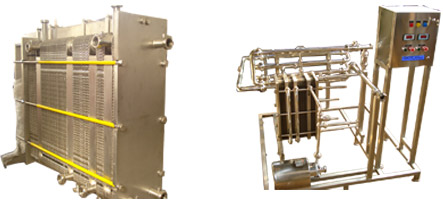

Milk Pasteurisers

| Capacity | : | 1000 LPH |

Model |

: |

H . T. S. T ( P - 22 type ) |

Temp. Prog. |

: |

Duty I 30 - 50 – 80 - 55 - 35 – 4 degree . C, |

Plates |

: |

S.S. 304 |

Heat transfer area/ plate |

: |

0.12 sq. mtr |

Total Heat transfer area |

: |

8.16sq. mtr |

No. Of plates |

: |

-------------- |

| Plate Thickness | : |

0.6mm |

Chilling media |

: |

Chilled water at 1.5 degree.C, @ 3 times the milk flow |

Heating media |

: |

Hot water at 85 degree .C, @ 2 times the milk flow |

Heat Regeneration |

: |

90% |

Pressure drop |

: |

Shall be minimum and party to specify the same. |

Holding |

: |

20 seconds, in pipe tubes. |

Gaskets |

: |

Foodgrade quality NBR capable of withstanding high temp . of 80 degree C. & 2 % caustic solution. |

Thermowells |

: |

For all inlets & outlets of PHE and each pocket shall be provided with s.s. guard of at least 200 mm length and glass thermometer. |

Frame |

: |

The supporting frame shall be of self supporting type. The frame & pressure plate of the unit shall be cladded with ss 304 and will be provided with adjustable ball feet. |

Inlets & outlets |

: |

The inlets & outlets in each section for products as well as services shall be provided with complete SMS unions. |

Tools |

: |

One no. “ C “ Spanner |

Drawings & Manuals |

: |

Two sets of plate diagram details & Instruction manual |

Milk Inline Strainers

| Functional Requirement | : | It will be installed in milk pipelines |

Capacity |

: |

5000 Lph, 38 / 51 mm ( Inlet / Outlet ) |

Constructional Features |

: |

Casing for 5,000 LPH |

Casing for 10,000 LPH |

||

Inlet / Outlet |

||

Filtering Element |

: |

S.S 18 guage perforated screen of 1mm / 1.5 mm holes having ring |

Blank Nut |

: |

S.S 304 grooved blank size -76 SMS fitted at opposite to the inlet end for easy removal of filtering element for cleaning. |

Milk Silos

Capacity in litres |

Overall Dia. mm |

Overall height. mm |

Overall weight kg |

Agitator H.P. |

| 20,000 | 2824 | 4405 | 3200 | 2.0 |

| 30,000 | 3060 | 5654 | 5000 | 3.0 |

| 40,000 | 3060 | 6954 | 5600 | 3.0 |

| 60,000 | 3810 | 7200 | 7800 | Air Agitat |

| 1,00,000 | 3810 | 11060 | 10,000 | Air Agitat |

All controls necessary for operating the tank are contained in the alcove

Flat pitched bottom construction with its network of bracing welded to bottom.

ank can be equipped with mechanical agitation or air agitation.

Provision for mounting level transmitter.

Standard accessories will be outlet cum inlet valve, CIP spray ball, Man-way door with sampling cock, Dial type thermometer

Milk Weigh Bowls

Slope |

: |

1:8 towards the outlet (from three sides) |

Finish |

: |

All welding joints are to be ground smooth and all s.s. surfaces to be polished to 150 grits |

The Bowl |

: |

The bowl shall be fabricated from 2.0 mm thick s.s. 304 quality material. The top edges shall be bent outward. It should be suitable to be suspended from the weigh scale |

Outlet Valve |

: |

The outlet valve will be mechanically operated from the reading position. The valve will be complete with disc, gasket, s.s. chain for hanging valve . |

Capacity |

: |

120 liter, 300 ltr. , 600 ltr |